Our workshop services are designed to provide comprehensive solutions for your wind turbine and industrial gearbox maintenance needs.

With a fully equipped facility and a team of expert technicians, we take on the heavy lifting so you can focus on your business. Our goal is to get your equipment back to peak condition with precision repairs, overhauls, and testing that ensures reliability and extended performance.

Minimise downtime with streamlined repairs. Our expert team ensures fast, thorough solutions using advanced tools for repairs that last.

Advanced Repair Solutions

When your equipment needs more than an onsite repair can address, our workshop is ready to provide a full spectrum of repair services.

We handle everything from component replacement to complete gearbox overhauls, giving you confidence in the reliability of your machinery. Our technicians are trained to meticulously strip down, inspect, and rebuild each unit, making sure that every part operates flawlessly.

We understand that downtime is expensive, so our repair services are streamlined for efficiency. Our experienced team works quickly and thoroughly, using advanced tools and technology to ensure a quality repair that stands the test of time.

Our Workshop Capabilities

Comprehensive Inspection

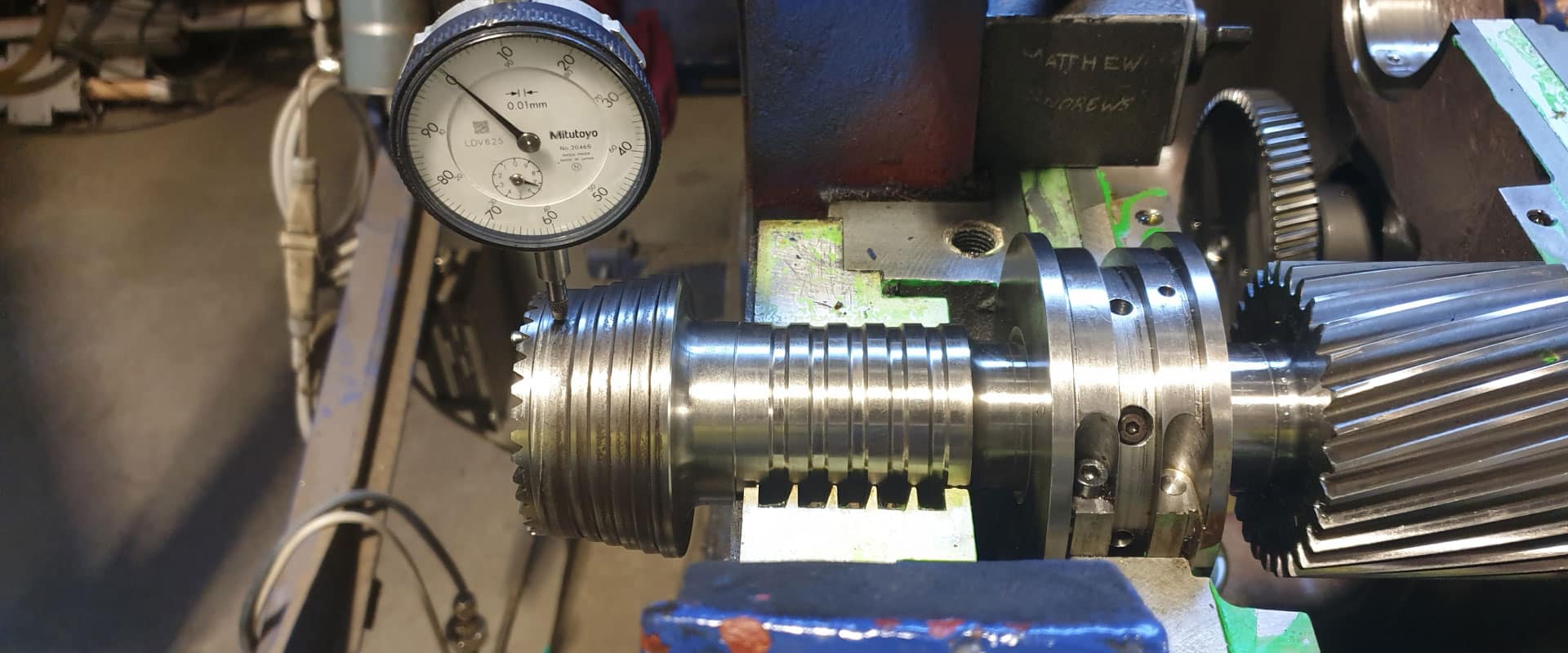

We conduct full inspections on all incoming gearboxes, using advanced diagnostic tools to identify wear and maintenance issues. Every inspection is documented to provide you with clear information on the status of your equipment.

Component Replacement and Repairs

From bearings to gears, we replace faulty components with precision, ensuring your machinery operates at its best.

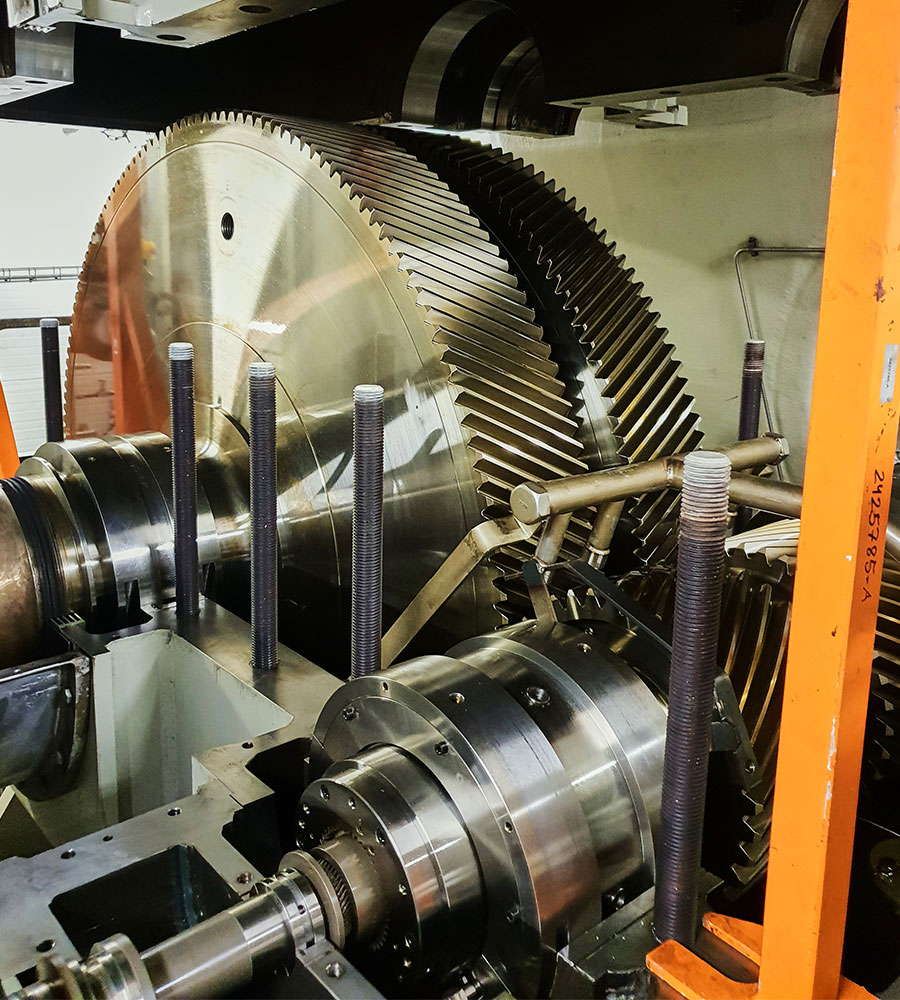

Gearbox Overhauls

Our complete overhaul services extend the life of your equipment, restoring functionality and reducing the risk of future breakdowns.

Testing Facilities

We conduct rigorous spin tests and vibration analysis to verify the performance of your repaired gearbox before it leaves our workshop, ensuring it’s ready for reliable operation.

State-of-the-Art Facility

Our workshop is equipped with the latest tools and technology to provide a wide range of repair services. From Computer Numerical Control (CNC) machining, including 5-axis and manual machines, to specialized equipment for non-destructive testing, we have everything needed to deliver precision and quality.

Hydraulic Hi-Torque Equipment

Essential for precise adjustments and repairs.

Bearing Heaters

Up to 300kg for safe installation and removal of critical components.

Gear Unit Testing

Including vibration analysis and detailed reporting to ensure the integrity of each gearbox.

CNC Machining

For accurate component fabrication and modification, including support from our parent company, Andrews & Rech.

20 ton & 10 ton gantry crane

Capable of handling heavy components, ensuring that we can work on even the largest industrial gearboxes.

Laser Alignment

To ensure components are perfectly aligned for optimal operation.

Root Cause Analysis

Detailed analysis of gear and bearing failures to prevent recurrence.

Gear Grinding

For precise finishing and refurbishment of gear components.

Paint Booth & Parts Cleaning Tank

Ensuring all components are cleaned and restored to the highest standards before reassembly.

The GT Technologies Difference

Precision Repairs and Overhauls

Our meticulous approach ensures every component is restored to optimal condition, reducing the risk of unexpected breakdowns.

Rigorous Testing

Before any equipment leaves our facility, we conduct thorough testing to guarantee that it meets our high standards for performance and reliability.

Full Documentation

We provide detailed inspection reports and testing documentation, giving you complete transparency and peace of mind.

Quality You Can Trust

Quality is at the heart of everything we do. We align our procedures with ISO 9001 standards, ensuring that every repair meets the highest benchmarks for safety, reliability, and performance.

Our partnership with Andrews & Rech means that we leverage decades of machining experience, bringing the capabilities of a major engineering powerhouse to each and every job.

Ready to Get Started?

With GT Technologies, you’re not just getting a repair – you’re getting a commitment to excellence that keeps your operations running efficiently. Our workshop services are here to ensure your equipment remains reliable, safe, and ready to perform.

If you need an overhaul or a precision repair, our workshop is equipped and ready to assist.